Some attributes of Electro Magnets:

Features of Mangla Hoists Electromagnets

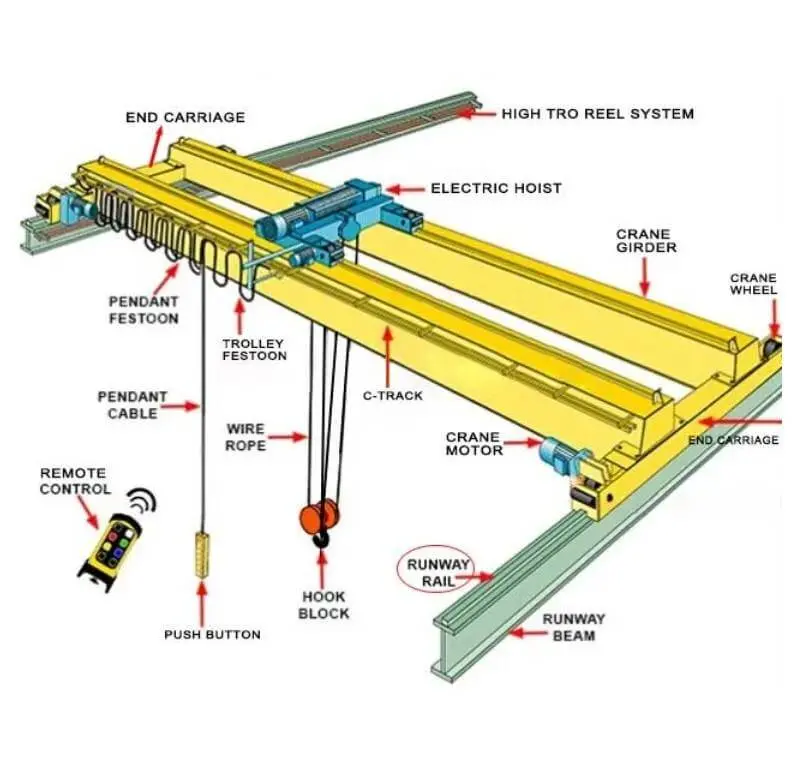

Choose the right type of overhead crane, the right capacity, span (depending on the height and width), the height of lift, power supply (voltage, phase, hertz), traveling length, operation, the usage of the crane and application (industry/environment).

Mangla after-sales services include these services so that you do not incur unnecessary expenditure:

1. Onsite crane installation

2. Training and operating instructions

3. Part repair and maintenance

4. Technical support

Scrap iron lifting (also known as electromagnetic chuck or scrap iron electromagnet, lifting electromagnet, scrap electromagnet) the main purpose is to lift iron. Since the material is low density and lighter than iron, heavy-duty electromagnets are used for lifting iron.

Steel pipe lifting electromagnets are ideal for high pressure and high-frequency load settings.

Excavator electromagnets cranes are quick and convenient and are installed in an excavator.

Automatic electromagnets are highly durable electromagnet cranes that are suitable for 24 hours of non-stop work environments.

Higher hoisting is required for higher density materials, and lower hoisting is required for lower density loads. If the electromagnets flickers, then it shows that the magnet might be weak or is not enough for the load. It might have been exposed to water or rain, causing a situation where it's waterproof performance is degraded. Kindly call the Mangla Hoists service center for electromagnet crane servicing.

Copyright © Mangla Hoists Private Limited. All Rights Reserved.