Mangla’s sole objective is to make its client’s experience pleasant and safe. We continuously strive to customize, innovate and improve on manufacturing as well as quality and after-sales service.

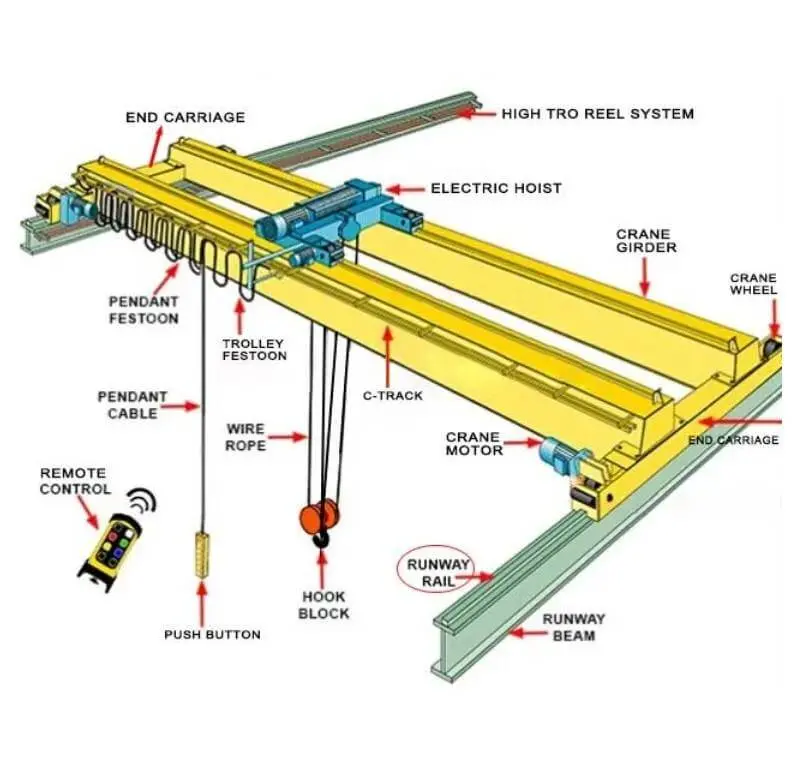

Some features of Mangla HOT cranes are:

| Bridge | IS 807/IS 3177/IS800 |

| End Carriages | Box type in construction & fabricated from the rolled section |

| L.T. Wheels | Two nos. straight type, En8 forged steel, double flanged LT wheels are provided in each of the two end carriages. These wheels are supported on steel axles. For underslung cranes S.G.I tapered type single flanged wheels are provided. |

| Pinion/Axle | Made from En9, heat-treated carbon alloy steel |

| Gears | IS 4460, made from EN 8 and are supported on ball bearings. |

| Bearings | The heavy-duty sealed ball bearing is used, thus regular lubrication is eliminated. Two ball bearing is provided in each wheel for smooth running. |

| Hook | IS 3815 / IS 15560. Made from forged steel - C20, C30 or equivalent. |

| Hoist | Chain pulley block. |

| Load Chain | Grade 80 alloy steel as per IS 6216. |

| Hand Chain | Grade 30 M.S. chain as per IS 2429. |

| Testing | 25% overload as per IS 3177. |

| 1T HH 150ae | 2T HH 150as | 3T HH 150a |

| 3T HH 150b | 5T HH 250a | 5T HH 250b |

| 7.5T HH 250al | 7.5T HH 250b | 10T HH 250a |

| 10T HH250bg | 15T HH 250b | 20T HH 250b |

Mangla provides complete installation support. Our professional team will assist you with the full installation of **HOT cranes**. We offer an excellent after-sales service, so you are covered, in case, it is required to dismantle the crane in future or if you need to shift it to any other location.

Yes, we do. Our professionals will visit your site and will not only help with the installation of **HOT cranes** but would also provide complete training on crane operations and safety.

The installation process is an easy task; however, we will help you in making this process convenient and hassle-free. Our experts will visit the site and do the needful.

Mangla is known for its high-quality norms in the industry. All cranes are manufactured as per the industry standards and our selection of quality components ensures **HOT cranes** have high resistance to vibrations and are durable, robust and reliable. Before choosing **HOT cranes**, you may check our list of happy customers.

Mangla cranes come with low-maintenance kits. But yes, every machine requires periodic maintenance due to usage and wear-tear. For this, our customer service team is always ready to help you.

Mangla cranes are as per IS standards and TUV ISO certified. When it comes to safety, we follow strict security norms to ensure our machines pass all quality and safety tests. Workforce safety is our top priority; we follow all safety norms and standards in the manufacturing and installation of cranes. Each crane is tested on full load and 25% overload at our works and all parameters inspected before dispatch.

We would love to review the project and suggest the best options. Our site experts will visit your facility to examine your requirements and suggest the best possible solution as per your business needs.

Copyright © Mangla Hoists Private Limited. All Rights Reserved.